A recent summary article published by the Journal of the American Academy of Orthopedic Surgeons discusses an important topic in total hip replacement surgery. see full article.

We looked into this paper and believe there are a few major concepts worth discussing.

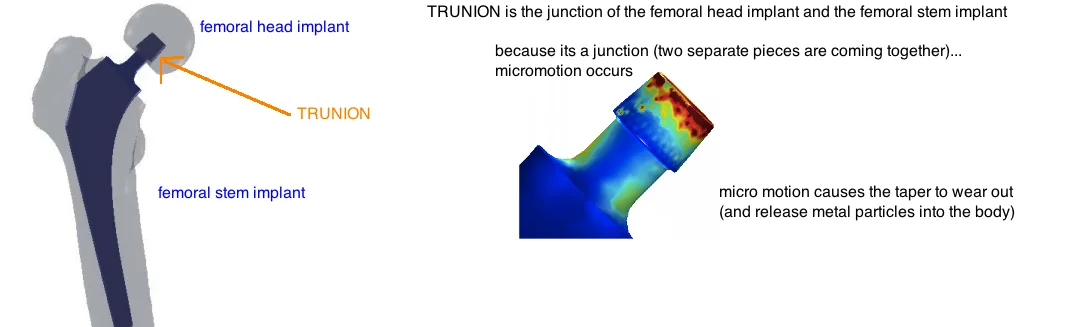

1) What is trunionosis?

The trunion is the junction of the femoral head and the femoral stem in a hip replacement. Trunionosis is a type of implant wearing out at this junction. It occurs where the femoral stem component attaches to the femoral head component. Even though these two parts fix together very tightly, there is always some minor micro-motion, which adds up over time, and over millions and millions of cycles, small metal debris is released into the joint. These metal particles can create an inflammatory response that causes pain and loosening of the hip implant itself, which further causes pain and may even require a revision surgery.

2) Dissimilar metals promote corrosion at the trunion.

Titanium is the ideal metal for a femoral stem because its modulus of elasticity is most similar to bone of all the metals. However, titanium is not an ideal metal for the femoral head because titanium is too soft and wears quickly if its part of the articulation. In contrast, Cobalt-Chrome is a great metal for the femoral head because its strong and tough and doesnt wear out easily over time. However, Cobalt-chrome is a little too tough to be used as a stem, its so rigid that it doesnt fit in smoothly in the canal, and causes thigh pain by being so stiff. Therefore a lot of surgeons like to mix-and-match. The problem with this is that when you combine dissimilar metals (like cobalt-chrome and titanium) in a fluid, you allow electron transfer to occur between the metals...another name for this is a Battery (you are creating a small battery in the hip). The result is that one metal wears out in a process called galvanic corrosion.

However, corrosion has also been seen in similar metals. Therefore, this chemical reaction is not the only thing responsible for the corrosion. The micro-motion also causes corrosion, and this is called mechanical assisted crevice corrosion.

3) There is no standardized design of the taper (the femoral neck part of the trunion).

There are over 30 different taper designs. It is believed that they do not all provide the same level of fixation to the femoral head. Tapers that are worse at forming a stable fixation will lead to increased micromotion and crevice corrosion. Because the tapers are not universal, you cannot mix and match femoral heads from different companies because they may not join together. Its believed that a shorter taper will lead to a smaller trunion length (ie less surface area between the femoral head and neck) which in turn means less interference fit and therefore more micromotion. The 12mm/14 mm size is by far the most commonly used over the past 20 years. Increased rigiditiy of the trunion decreased corrosion. Also, Larger femoral heads increase the torsion on the trunion. This leads to greater micromotion and therefore higher rates of corrosion.

4) What is fretting?

Metals have a layer of protective ions which are inert and prevent reaction with the body environment. However, fretting occurs when this surface layer is removed, and increases metal exposure to the body environment speeding up the corrosion.

5) How to treat trunionosis in a well fixed stem.

The next question is what to do when you see trunionosis. If the femoral stem is well fixed, do you need to rip the whole stem out? This makes a hip revision surgery much more complicated. There is no solid evidence to suggest that this needs to be done. The taper should be cleaned, with a dry lap pad, or even scratched a little with the bovie cleaner. Placing a new femoral head on a cleaned-up taper appears to have good short term outcomes without a high revision rate (no repeat trunionosis). Its also a good idea to avoid placing a cobalt-chrome head back into the person because they may be sensitized to the metal particles. A ceramic head is at increased risk of breaking if put onto a roughened taper, however, if you place a titanium sleeve to protect it, there isnt that risk of ceramic fracture.

References

1) Collier JP, Surprenant VA, Jensen RE, Mayor MB: Corrosion at the interface of cobalt-alloy heads on titanium-alloy stems. Clin Orthop Relat Res 1991;271:305–312. 56% corrosion rate when dissimlar metals are combined such as titanium stem and co-cr head. which is ideal for preventing stress shielding while promoting logevity of the head. full article.

2) Collier JP, Surprenant VA, Jensen RE, Mayor MB, Surprenant HP: Corrosion between the components of modular femoral hip prostheses. J Bone Joint Surg Br 1992;74(4):511–517. Dissimilar metals create a battery. Similar metals do not show any galvanic corrosion. full article.

3) Goldberg JR, Gilbert JL, Jacobs JJ, Bauer TW, Paprosky W, Leurgans S: A multicenter retrieval study of the taper interfaces of modular hip prostheses. Clin Orthop Relat Res 2002;401:149–161. Corrosion is also seen in similar metal combos. full article.

4) Gilbert JL, Buckley CA, Jacobs JJ: In vivo corrosion of modular hip prosthesis components in mixed and similar metal combinations: The effect of crevice, stress, motion, and alloy coupling. J Biomed Mater Res 1993;27(12):1533–1544. Leading hypothesis on corrosion in THA. full article.

5) Cook RB, Bolland BJ, Wharton JA, Tilley S, Latham JM, Wood RJ: Pseudotumour formation due to tribocorrosion at the taper interface of large diameter metal on polymer modular total hip replacements. J Arthroplasty 2013;28(8):1430–1436. Length of trunion affects the corrosion. full article.

6) Burroughs BR, Muratoglu OK, Bragdon CR, et al.: In vitro comparison of frictional torque and torsional resistance of aged conventional gamma-in-nitrogen sterilized polyethylene versus aged highly crosslinked polyethylene articulating against head sizes larger than 32 mm. Acta Orthop 2006;77(5):710–718. Increased torsion on trunion with larger femoral heads. full article.

7) Fricka KB, Ho H, Peace WJ, Engh CA Jr: Metal-on-metal local tissue reaction is associated with corrosion of the head taper junction. J Arthroplasty 2012;27. MoM has greater trunion wear that Metal on poly suggesting that bearing surface plays an important role. full article.

8) Huot Carlson JC, Van Citters DW, Currier JH, Bryant AM, Mayor MB, Collier JP: Femoral stem fracture and in vivo corrosion of retrieved modular femoral hips. J Arthroplasty 2012;27(7):1389–1396.e1, Ceramic heads may be a solution to this. full article.

9) Pennock AT, Schmidt AH, Bourgeault CA: Morse-type tapers: Factors that may influence taper strength during total hip arthroplasty. J Arthroplasty 2002;17(6):773–778. Morse taper is best fit when formed in a dry environment. full article.

10) Goyal N, Ho H, Fricka KB, Engh CA Jr: Do you have to remove a corroded femoral stem? J Arthroplasty 2014;29(9 suppl):139–142. ok to retain a well fixed stem. short term outcomes. full article.